Wastewater, whether urban or from farms, may not look or smell good. But to University of Auckland researchers, it can be the source of agricultural gold – well, a whitish-goldish mineral called struvite, anyway. Phosphorus-rich struvite not only makes a great slow-release fertiliser, recovering it from wastewater helps clean up our waterways.

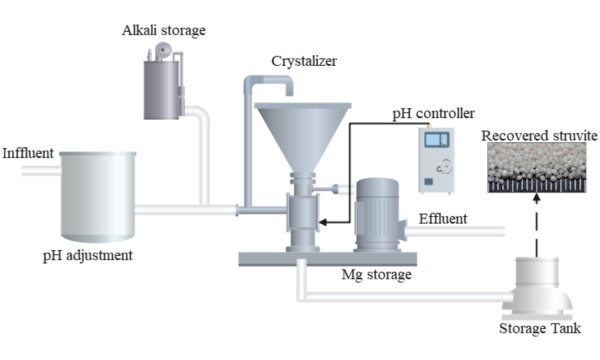

Senior Lecturer Wei Yu and Research Fellow Bing Li of Chemical and Materials Engineering have been researching phosphorus recovery for years. They’re now ready to take the next step and pilot their process on a commercial scale. They say it will not only be good for the planet, it will also make financial sense.